Once the price product quality match is made, customer places the order. Only the mutually agreed specifications are taken to the production line and carefully monitored at each level.

We provide two types of splints- Indian Malabarica and Imported Poplar. The splints are selected as per client's PO and then dipped in the head chemical.

The reels of inner box material are fed through high speed automated machines with the size requirements as per the PO. The boxes are then filled with splints using box filling machine with the pre-set stick count.

Outer box is made of coated duplex board with GSM mentioned by the client. The boards are printed as per client’s design and cut in to pre-set size after applying side friction chemical. The skillets are then made in to outer box using automated machinery, which then runs in to the combination line where the inner box and outer box are combined.

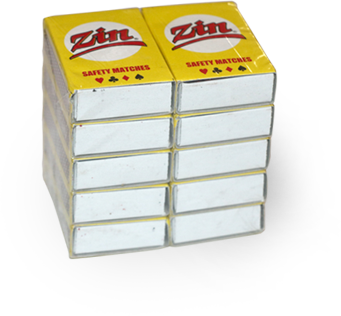

10 match boxes are packed together using PVC/Printed paper packing as per client demand

10 x 10’s pack are packed together using shrink/polybag to form a 100s packing

10 x 100’s pack are packed together in a 3 Ply carton box to form final packing

Container is loaded finally as per the PO issued by client using forklifts in the presence of quality inspectors and 3 rd party inspectors as nominated by the client.